Multicrystalline silicon solar energy requires an inverter

Welcome to our dedicated page for Multicrystalline silicon solar energy requires an inverter! Here, we have carefully selected a range of videos and relevant information about Multicrystalline silicon solar energy requires an inverter, tailored to meet your interests and needs. Our services include high-quality Multicrystalline silicon solar energy requires an inverter-related products and solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

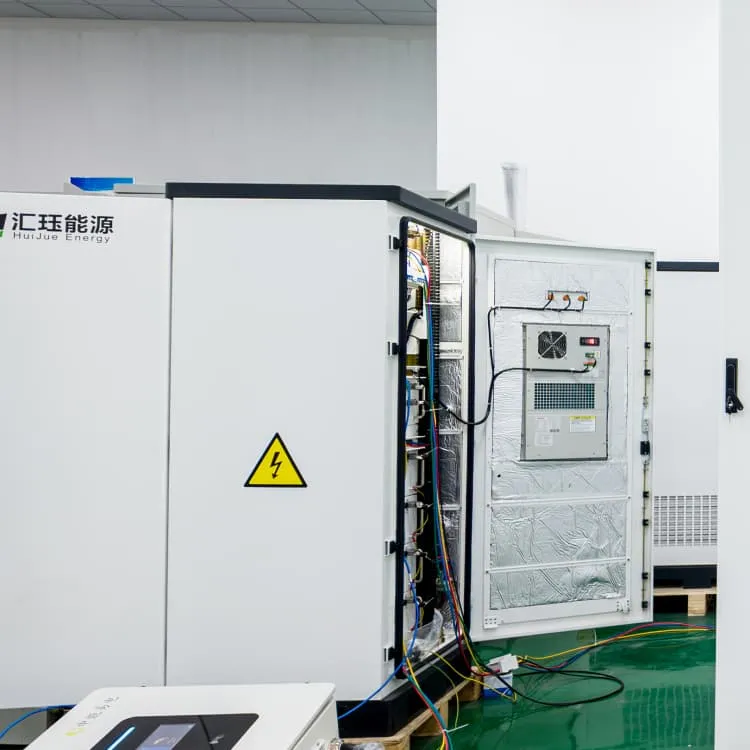

Wherever you are, we're here to provide you with reliable content and services related to Multicrystalline silicon solar energy requires an inverter, including cutting-edge home energy storage systems, advanced lithium-ion batteries, and tailored solar-plus-storage solutions for a variety of industries. Whether you're looking for large-scale industrial solar storage or residential energy solutions, we have a solution for every need. Explore and discover what we have to offer!

Life Cycle Analysis of Solar PV System: A Review

Nawaz evaluated the embodied energy for production of the crystalline silicon PV modules and BOS components and estimated that embodied energy for open filed and roof-top PV systems

Performance evaluation of 50 kWp bifacial multi

Bifacial photovoltaics (PVs) offer a promising pathway to enhancing electrical conversion efficiency and energy yield compared to

Crystalline silicon cell performance at low light intensities

The various multi-crystalline silicon (mc-Si) and mono-crystalline silicon (c-Si) cell sample manufacturer codes, the overall number of samples from each supplier and the

What is Multicrystalline Silicon?

Multicrystalline silicon is also known as polycrystalline silicon. It is a widely used material in photovoltaics or solar cells. It differs from

Demystifying Polycrystalline Solar Panels: How They Operate

How do polycrystalline solar panels work? Learn their mechanics and explore the advantages they bring to sustainable energy solutions with Freyr Energy.

A comparative life cycle assessment of silicon PV modules:

Monofaciality is chosen for both designs to allow for a fair comparison, e.g. no additional rear-side electricity gain for G-G modules through bifaciality. Single-crystalline

Energy requirement for manufacturing of multi

Energy requirement for manufacturing of multi-crystalline silicon module (Multi-Si) photovoltaic (PV) plants. The expansion of photovoltaic solar energy in the

A comparative life-cycle assessment of photovoltaic electricity

This paper presents a comparative life-cycle assessment of photovoltaic (PV) electricity generation in Singapore by various p-type multicrystalline silicon (multi-Si) PV

Silicon Solar Cell

Abstract Silicon solar cells have been an integral part of space programs since the 1950s becoming parts of every US mission into Earth orbit and beyond. The cells have had to survive

MULTICRYSTALLINE SILICON

Seed-assisted growth such as Quasi-Mono and high performance multicrystalline silicon also looks promising. All of these processes require good temperature control. Ideally, the

Reaching Grid Parity Using BP Solar Crystalline Silicon

Silicon purification − Process development of solar grade silicon. − Use of SoG Si in Casting. Casting − Implementation of Mono2TM technology (single crystal quality at multicrystalline

Photovoltaic Cell Generations and Current Research

In particular, the third generation of photovoltaic cells and recent trends in its field, including multi-junction cells and cells with intermediate energy levels in the

Life cycle assessment for a grid-connected multi-crystalline silicon

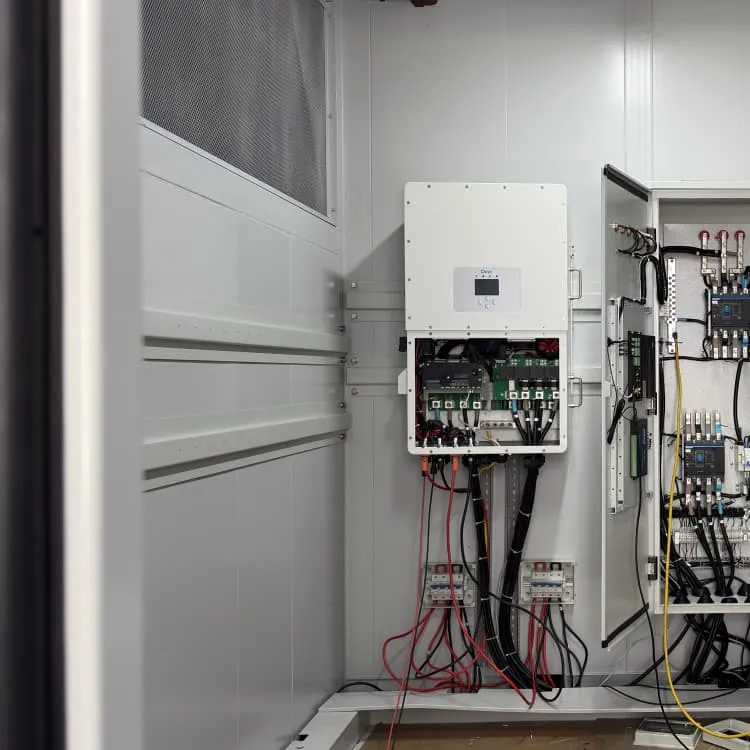

The photovoltaic system consists of 12 modules integrated with a multi-crystalline silicon technology with a southward inclination of 20°, a 2.5 kW inverter, and a total installed

Solar Cells on Multicrystalline Silicon Thin Films Converted from

Fabrication and characterization of solar cells based on multicrystalline silicon (mc-Si) thin films are described and synthesized from low-cost soda-lime glass (SLG).

Multicrystalline Silicon Cell

The inherent inefficiency of PV modules is due to the fact that many of the electrons that have absorbed some energy from low-energy photons do not hold onto that energy long enough to

02-24-02260fso-2003

In this study, normalized performance indices [20] were es-timated for a 50 kWp bifacial multi-crystalline silicon (multi-c-Si) solar photovoltaic energy system.

Multi-Crystalline Silicon

The manufacturing of solar panels is a process that requires a particular type of silicon, known as Multi-Crystalline Silicon. This silicon variant proves to be a valuable asset in the production of

Measuring Instrument

Measuring Instrument: Gauging Tools Play A Crucial Role In Assessing The Efficiency Of Solar Panels Types of Solar Energy Measuring Instruments Solar energy continues to grow in

Polycrystalline Solar Panels: Efficient & Affordable

Solar energy is the future of clean and renewable energy sources. With the advancement in technology, solar panels have become more efficient and cost

Multicrystalline Silicon Solar Cell Manufacturing

The manufacturing process typically involves directional solidification of molten silicon, where controlled grain growth and impurity management are critical to achieving high conversion...

Monocrystalline silicon

Monocrystalline silicon is the base material for silicon chips used in virtually all electronic equipment today. In the field of solar energy, monocrystalline silicon is also used to

Photovoltaic Cell Generations and Current Research Directions

In particular, the third generation of photovoltaic cells and recent trends in its field, including multi-junction cells and cells with intermediate energy levels in the forbidden band of silicon, are

Working on Solar Wiring and Fusing (EB-2023-0676)

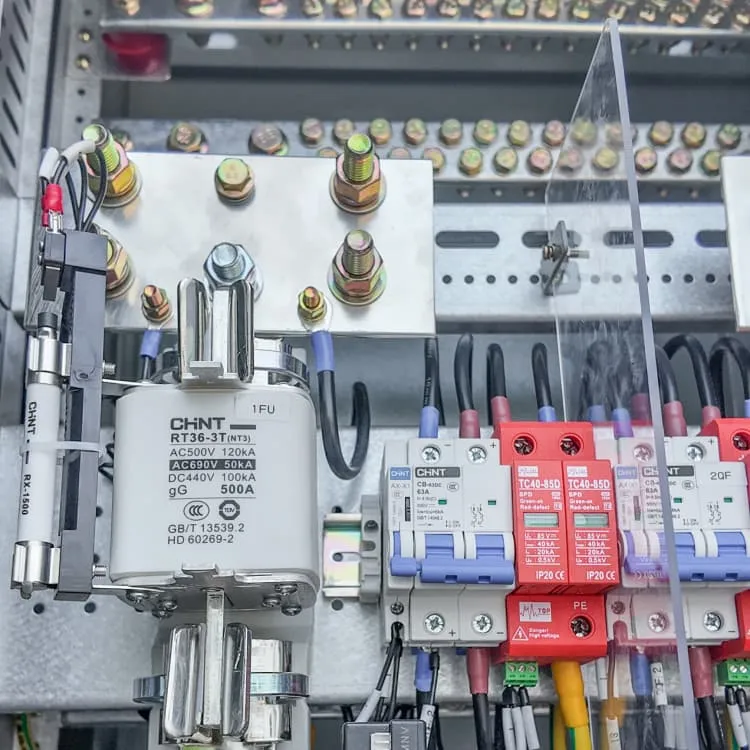

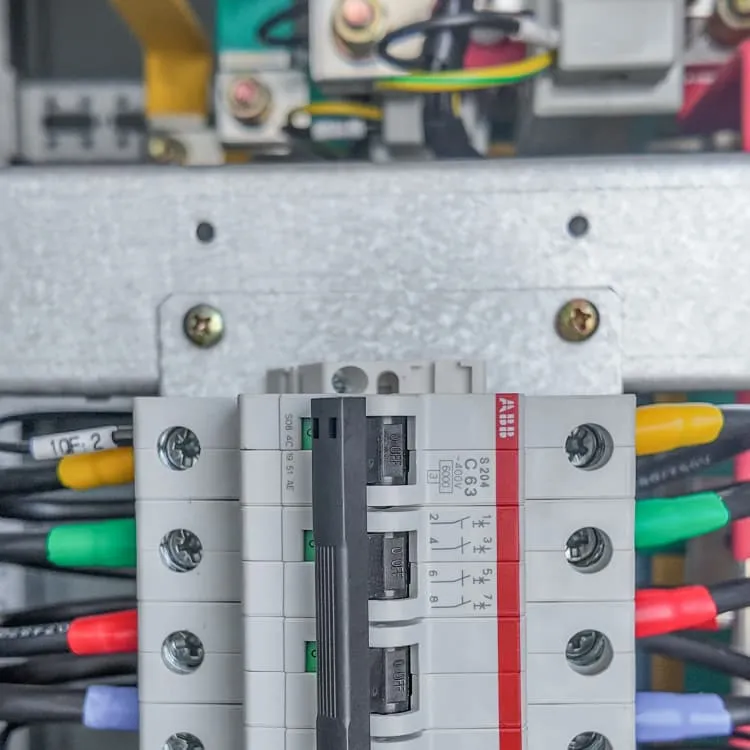

Wiring and overcurrent protection devices (such as fuses and circuit breakers) can be sized, selected and integrated with your solar PV system once the solar array and other electrical

Energy requirement for manufacturing of multi-crystalline silicon

Energy requirement for manufacturing of multi-crystalline silicon module (Multi-Si) photovoltaic (PV) plants. The expansion of photovoltaic solar energy in the world is significant....

Photovoltaic Ch 11 Electrical Integration Flashcards

For an interactive inverter with the PV output circuit connected directly to the inverter input, the inverter input circuit is the same as the PV output circuit

What is Multicrystalline Silicon?

Multicrystalline silicon is also known as polycrystalline silicon. It is a widely used material in photovoltaics or solar cells. It differs from monocrystalline silicon as it consists of

Performance evaluation of 50 kWp bifacial multi-crystalline silicon

Bifacial photovoltaics (PVs) offer a promising pathway to enhancing electrical conversion efficiency and energy yield compared to standard monofacial PV systems. This

Status and perspectives of crystalline silicon photovoltaics in

Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

FAQs 6

What is the difference between monocrystalline and multicrystalline silicon solar cells?

Good Energy Conversion Efficiency: While multicrystalline silicon typically exhibits slightly lower energy conversion efficiency compared to monocrystalline silicon, it still provides satisfactory performance. Advances in casting techniques and material quality have contributed to the improved efficiency of these silicon solar cells over time.

How efficient is a 50 KWp bifacial multi-crystalline silicon solar PV system?

This study investigated the performance of a 50 kWp bifacial multi-crystalline silicon solar PV system. Simulation results indicate an annual net AC energy output of 79281.8 kWh and a net DC yield of 84763.7 kWh, corresponding to a performance ratio of 64.47 %, based on a nominal plane of array irradiance of 525330 kWh.

What is multicrystalline silicon?

Multicrystalline silicon is also known as polycrystalline silicon. It is a widely used material in photovoltaics or solar cells. It differs from monocrystalline silicon as it consists of multiple crystal structures, characterized by small crystalline regions.

Why do we need crystalline silicon for photovoltaic (PV) energy conversion?

Crystalline silicon is needed in large and ever-increasing amounts, in particular for photovoltaic (PV) energy conversion. Efficient thin-film absorbers, for example, based on abundant and stable compound semiconductors, were considered to reduce material consumption.

Why are solar cells dominated by monocrystalline silicon?

It is noted that the solar cell market is dominated by monocrystalline silicon cells due to their high efficiency. About two decades ago, the efficiency of crystalline silicon photovoltaic cells reached the 25% threshold at the laboratory scale. Despite technological advances since then, peak efficiency has now increased very slightly to 26.6%.

Why is polycrystalline silicon a good choice for solar panels?

Enhanced Heat Tolerance: Polycrystalline silicon demonstrates good heat tolerance, enabling it to perform well under high operating temperatures. This characteristic is crucial for solar panels that are exposed to varying temperature conditions.

Related links

- Multicrystalline silicon double-glass solar panels

- Monocrystalline silicon solar panel inverter

- Inverter Silicon Energy Battery

- Inverter solar energy storage cabinet photovoltaic

- Solar all-in-one machine requires an inverter

- Solar energy storage photovoltaic panel water pump inverter

- Solar energy can drive water pump inverter

- Does wind and solar energy storage require an inverter

- How to use solar energy with a 220V water pump inverter

- Solar energy storage and inverter integrated machine