It takes time to produce battery cabinets with lithium carbonate

Welcome to our dedicated page for It takes time to produce battery cabinets with lithium carbonate! Here, we have carefully selected a range of videos and relevant information about It takes time to produce battery cabinets with lithium carbonate, tailored to meet your interests and needs. Our services include high-quality It takes time to produce battery cabinets with lithium carbonate-related products and solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

Wherever you are, we're here to provide you with reliable content and services related to It takes time to produce battery cabinets with lithium carbonate, including cutting-edge home energy storage systems, advanced lithium-ion batteries, and tailored solar-plus-storage solutions for a variety of industries. Whether you're looking for large-scale industrial solar storage or residential energy solutions, we have a solution for every need. Explore and discover what we have to offer!

Lithium carbonate production project banks on brine

It can take a year or more to produce high-concentrated lithium brines. During that time, the large, but shallow evaporation ponds go through various stages requiring accurate

Lithium Brine Extraction Technologies & Approaches

This can be further purified to produce battery-grade lithium by re-dissolving the lithium carbonate, and then using an ion exchange process to remove impurities.

Technical Guide for the Production of High Purity Lithium

This Technical Guide for the Production of High-Purity Lithium Carbonate (Battery Grade) provides a comprehensive overview of the processes, equipment, and logistics involved in

Hatton & Berkeley

The first step involves treating the lithium carbonate with caustic soda (sodium hydroxide) to produce a mixture of sodium carbonate and lithium hydroxide. The second step is the

From Raw Materials to Finished Product: The Lithium

Once the lithium is extracted, the raw lithium needs to undergo purification to become battery grade lithium. The purification takes two forms

E3 Lithium Advances Battery-Grade Lithium

Calgary-based E3 Lithium, a leader in Canadian lithium production, has successfully commissioned its demonstration-scale carbonate

Lithium sulfate battery production process

A Look Into the Lithium-Ion Battery Manufacturing Process. The lithium-ion battery manufacturing process is a journey from raw materials to the power sources that energize our daily lives. It

Artificial intelligence-enabled optimization of battery-grade lithium

In this study, we propose a Bayesian active learning-driven high-throughput workflow to optimize the CO 2 (g) -based lithium brine softening method for producing solid

Ascend Elements to Produce Lithium Carbonate from

US battery company Ascend Elements has announced that it will be operating a new recycled lithium carbonate production line at its Covington

E3 Lithium Advances Battery-Grade Lithium Carbonate Production

Calgary-based E3 Lithium, a leader in Canadian lithium production, has successfully commissioned its demonstration-scale carbonate conversion reactors, marking a

Overview of Lithium Processing: Evaporative Brine and DLE

The solid Lithium Carbonate product is collected using a centrifuge. A regenerable filter at location (5) is used to capture any carryover solids from the centrifuge in the mother liquor before it is

Lessons Learned from Developing Battery-Grade Lithium Projects

The global market for lithium products is very attractive with the supply of raw materials falling behind the emerging demand growth in markets such as China. This paper

Technical Guide for the Production of High Purity Lithium Carbonate

This Technical Guide for the Production of High-Purity Lithium Carbonate (Battery Grade) provides a comprehensive overview of the processes, equipment, and logistics involved in

Lithium: From Rocks into Roadsters | by Carly

Based on the growth in demand from the battery sector and the time it takes to build new lithium production (5–10 years), the industry should

Artificial Intelligence-Enabled Optimization of Battery-Grade

ABSTRACT By 2035, the need for battery-grade lithium is expected to quadruple. About half of this lithium is currently sourced from brines and must be co (Li2CO3) through a process called

From Raw Materials to Finished Product: The Lithium Batteries

Once the lithium is extracted, the raw lithium needs to undergo purification to become battery grade lithium. The purification takes two forms i.e., lithium carbonate and

Lithium Extraction Methods

Discover the different lithium extraction methods: exploring greener alternatives and the game-changing technology of Lithium Harvest.

Brine to batteries: lithium extraction technology that''s

Moving on from MOFs Rechargeable lithium batteries either use lithium carbonate or lithium hydroxide depending on the type of battery. The

Battery grade lithium carbonate-fundamentals and applications

4. Challenges and prospects of battery grade lithium carbonate Although battery-grade lithium carbonate plays an important role in battery manufacturing, its production

Rio Tinto takes FID on $2.5 billion Rincón lithium project

Rincón, located in Salta province, will have the capacity to produce 60,000 tonnes/year of battery-grade lithium carbonate. With the investment approval, Rio plans to start construction of the

It takes time to produce lithium carbonate battery cabinets

The Company has now successfully demonstrated two separate crystallisation flowsheets that can take lithium chloride produced from the Smackover Formation brine and convert it into

A new process to produce battery grade lithium carbonate from

Thermal decomposition produced lithium carbonate solid from the loaded strip solution. The comprehensive yield of lithium was higher than 95%, and the quality of the

In-Depth Analysis of Lithium Battery Manufacturing Processes

In order to effectively examine the complexities of lithium battery manufacturing, a thorough methodology was implemented. The research is grounded in a mixed-methods approach,

SLB produces lithium 500x faster with 96% recovery rate from brine

It takes mere hours to extract lithium from brine and convert it to technical-grade lithiu m carbonate. The standard evaporation procedures take up to 18 months.

Lithium carbonate production methods and production process,

In this article, we will introduce in detail the production methods and production process of lithium carbonate, what are the commonly used raw materials, and understand the

What is Lithium Refining? A Deep Dive from EnergyX

Lithium is crystallized into battery-grade lithium hydroxide or lithium carbonate. The final product undergoes stringent quality control

FAQs 6

How to make lithium carbonate?

Carbonate Process Using Evaporation PondsLithium Processing – DLELithium brine can also be converted into Lithium Carbonate by Direct Lithium Extraction (DLE using an adsorption bed to separate out the Lithium from the brine. A schematic for making Lithium Carbonate is illustrated in Figure 3.The first step is pumping t

How is lithium carbonate collected?

The solid Lithium Carbonate product is collected using a centrifuge. A regenerable filter at location (5) is used to capture any carryover solids from the centrifuge in the mother liquor before it is recycled and to

How to convert lithium brine into lithium carbonate?

Lithium Carbonate from mother liquor recycle and wash water stream Protect RO filtration unit from fou Carbonate Process Using Evaporation PondsLithium Processing – DLELithium brine can also be converted into Lithium Carbonate by Direct Lithium Extraction (DLE using an adsorption bed to separate out the Lithium from the brine.

How is lithium carbonate filtered?

apture any particles that are present during the water wash process. The water use for rinsing the Lithium Carbonate solids is filtered at location (6) by a 10 micron filter and hen further purified using Reverse Osmosis (RO) membrane filtration. To obtain battery grad

What is lithium carbonate used for?

Lithium Carbonate: Lithium carbonate to be used in lithium battery applications is refined by purifying the raw lithium through processes such as carbonation, precipitation to remove contamination to a greater extent, thereby ensuring its high purity for lithium to be effectively used for battery grade.

How is a lithium ion battery manufactured?

Manufacturing lithium ion batteries is a complex procedure that involves a lot of activity. The lithium battery manufacturing process—required for each cell—includes lengthy, reproducible, and useful engineering and quality control steps.

Related links

- Lithium battery packs connected in parallel for a long time

- How many watts does a lithium battery inverter actually produce

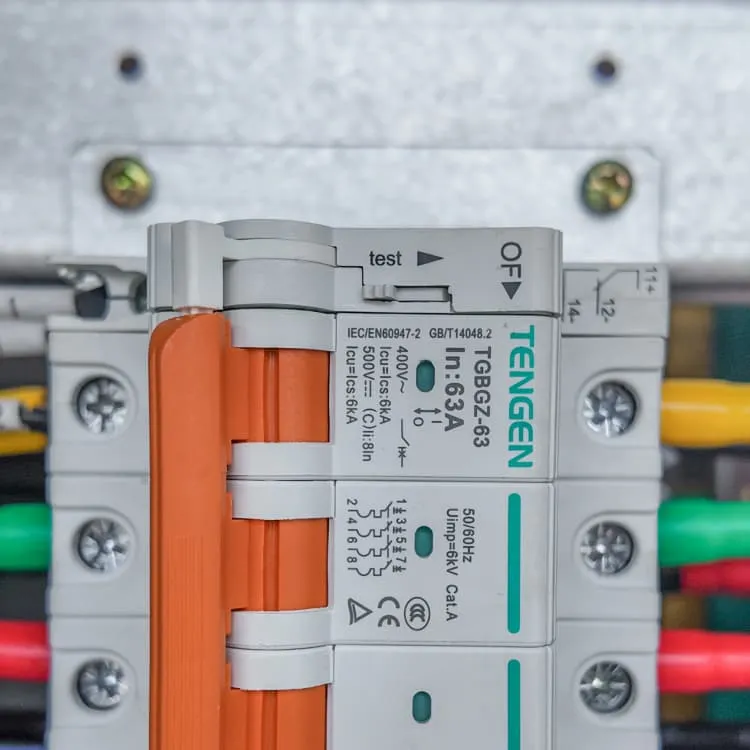

- What equipment is needed to produce lithium battery packs

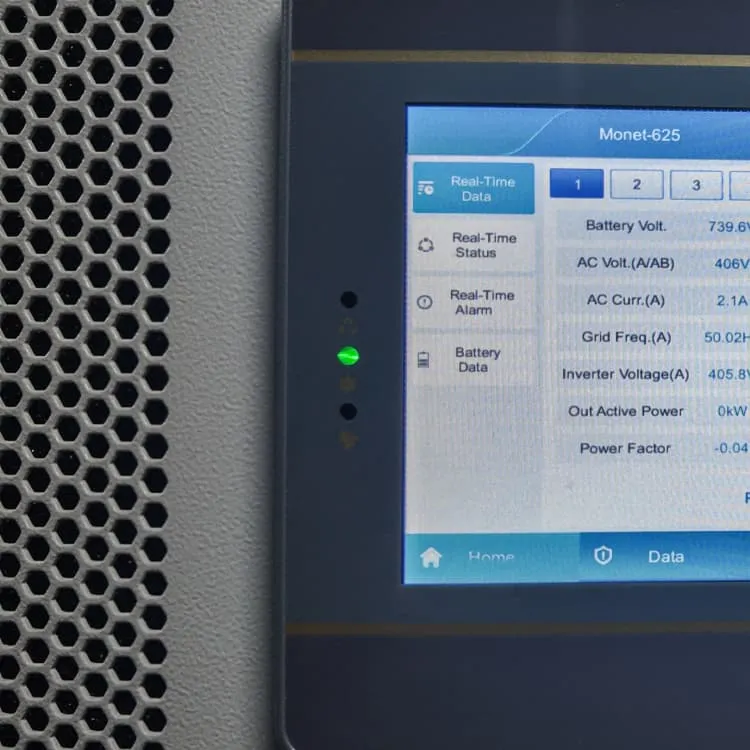

- Recommended brands of lithium battery outdoor power cabinets

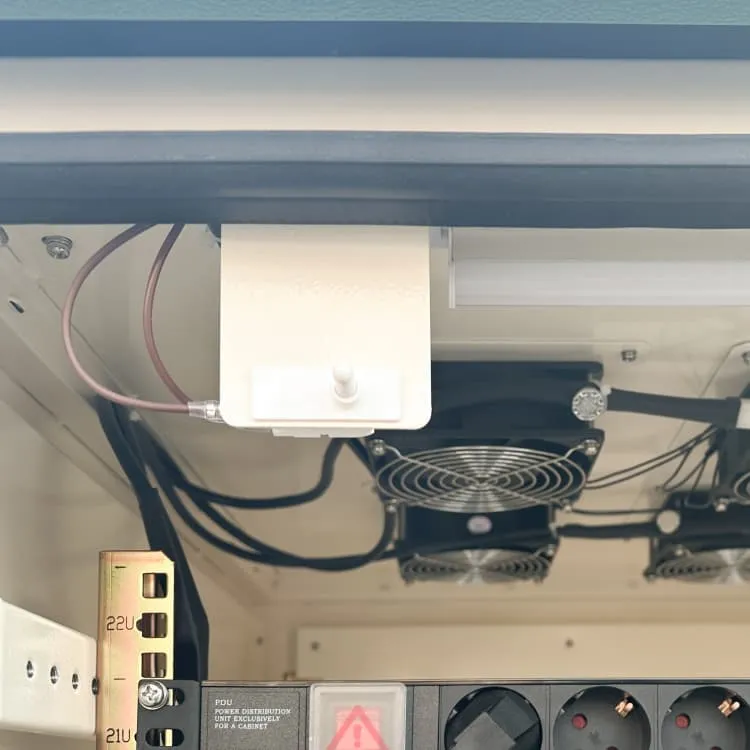

- Things to note about lithium battery energy storage cabinets

- What are the installation conditions for lithium battery station cabinets

- Manufacture of 220v lithium battery outdoor battery cabinets

- How to reuse power from lithium battery station cabinets

- Are lithium battery packs for energy storage cabinets expensive

- Battery time measurement of communication base station