Comoros pack lithium battery equipment production plant

Welcome to our dedicated page for Comoros pack lithium battery equipment production plant! Here, we have carefully selected a range of videos and relevant information about Comoros pack lithium battery equipment production plant, tailored to meet your interests and needs. Our services include high-quality Comoros pack lithium battery equipment production plant-related products and solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

Wherever you are, we're here to provide you with reliable content and services related to Comoros pack lithium battery equipment production plant, including cutting-edge home energy storage systems, advanced lithium-ion batteries, and tailored solar-plus-storage solutions for a variety of industries. Whether you're looking for large-scale industrial solar storage or residential energy solutions, we have a solution for every need. Explore and discover what we have to offer!

Low-carbon society green sharing Africa Comoros Mobile phone lithium

The Comoros islands of Greater Comoros, Anjouan, Moeli and Mayotte, which constitute the Comoros, are known as the four bright pearls in the Western Indian Ocean.

Comoros Lithium Ion Cell and Battery Pack Market (2024

Comoros Lithium Ion Cell and Battery Pack Market is expected to grow during 2023-2029

Lithium ion Battery Manufacturing Plant Cost Report 2024:

Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an lithium ion battery manufacturing plant. The report

Cheap 18650 Battery Pack Assembly Machine,18650 Battery Pack

As a professional battery manufacturing equipment Manufacturer,Tmax provides high quality 18650 Battery Pack Assembly Machine,learn more about 18650 Battery Pack Assembly

Lithium Battery Recycling Plant Setup in Comoros | Recycling

Setting up a Lithium Battery Recycling Plant in Comoros involves several key steps, including battery collection, discharge, dismantling, material separation, and refining.

Lithium Battery Equipment | Battery Manufacturing Machines | Battery

Commercial manufacturing and R&D lithium battery equipment solutions,and battery assembly equipment manufacturers. Vast selection of in stock battery manufacturing machines to

Comoros lithium battery pack

The Lithium Battery Pack is the final stage in Lithium production, which cannot be processed further and can be sold for $85,000. The player needs to sell 10x Lithium Battery Packs to

Battery Pack Assembly Machine | Battery Pack Manufacturers | Battery

Tmax is the most professional battery pack manufacturers,we offer high quality battery pack assembly machine and battery assembly machine for battery research and manufacturing.

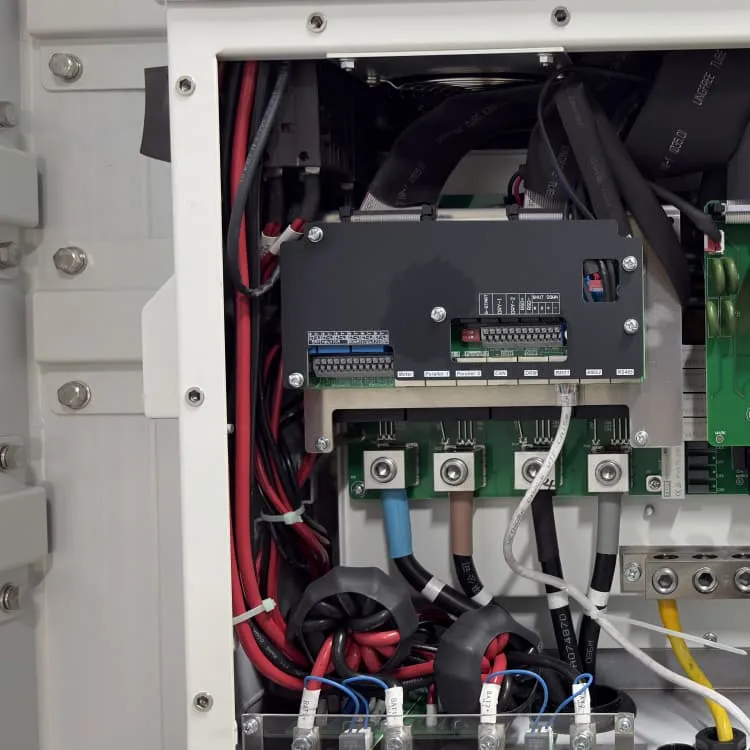

Lithium Battery Pack manufacturing Production Line

3 days ago· A lithium battery pack manufacturing production line is designed to efficiently produce highquality lithiumion or lithium ferro phosphate (LFP) battery packs, which are

Cell Manufacturing

Cell manufacturing is one part of the battery manufacturing chain, but perhaps one of the most difficult parts.

ABF Statement on Tucson, AZ

LEAD''s prowess extends across eight specialized manufacturing sectors, including lithium-ion EV batteries, EV module and pack equipment, solar PV panels, 3C equipment,

lithium-ion battery production lines

Our product portfolio starts after cell production and covers module and pack assembly for lithium-ion or sodium-ion batteries. We are developing, constructing and building customized

Battery plant technology: Cost-efficient battery production

Battery plant technology: Cost-efficient battery production High speed – high precision What are commonly called batteries in electric or hybrid vehicles are referred to by experts as battery

Lithium-Ion Battery Manufacturing Plant: Setup & Cost

The lithium-ion battery manufacturing plant report provides detailed insights into project economics, cost breakdown, setup requirements & ROI etc.

Lithium-ion Battery Pack Manufacturing Process & Design

This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

Battery Breaking and Separation Plant/ BBSP Cost

The cost varies based on equipment quality, production capacity, and the inclusion of eco-friendly waste management systems. A Battery Breaking and Separation Plant in Comoros operates

Battery production factory in Comoros

The plant, which began production of battery modules in 2021, received the green light from the German authorities to begin battery manufacturing in April. Currently, at 8 GWh capacity per

Comoros Electric Vehicle Battery Manufacturing Equipment

Historical Data and Forecast of Comoros Electric Vehicle Battery Manufacturing Equipment Market Revenues & Volume By Battery Production for the Period 2021-2031

Low-carbon society green sharing Africa Comoros Mobile phone

The Comoros islands of Greater Comoros, Anjouan, Moeli and Mayotte, which constitute the Comoros, are known as the four bright pearls in the Western Indian Ocean.

China''s new products boosts Comoros Lithium battery crushing

The Comoros is mainly engaged in the processing of agricultural products. There are also printing factories, pharmaceutical factories, Coca-Cola bottling factories, cement hollow brick factories

Lithium-Ion Battery Manufacturing: Industrial View on

Developments in different battery chemistries and cell formats play a vital role in the final performance of the batteries found in the market.

Lithium Battery Production Line,Supercapacitor

Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision

lithium-ion battery production lines

Our product portfolio starts after cell production and covers module and pack assembly for lithium-ion or sodium-ion batteries. We are developing,

Clean Room atmosphere requirements for battery

The core processes in lithium-ion battery manufacturing such as electrode manufacturing (steps 2 and 7) and battery cell assembly (step 8) are

Bikes Battery Assembly

Streamlining Production with the Lifeop4 Battery Pack Assembly Line As the demand for efficient, reliable, and sustainable energy storage solutions continues to grow, the Lifeop4 battery pack

FAQs 6

What is the lithium-ion battery manufacturing plant project report 2025?

IMARC Group’s report, titled “ Lithium-Ion Battery Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue, ” provides a complete roadmap for setting up a lithium-ion battery manufacturing plant.

What is a lithium-ion battery manufacturing plant?

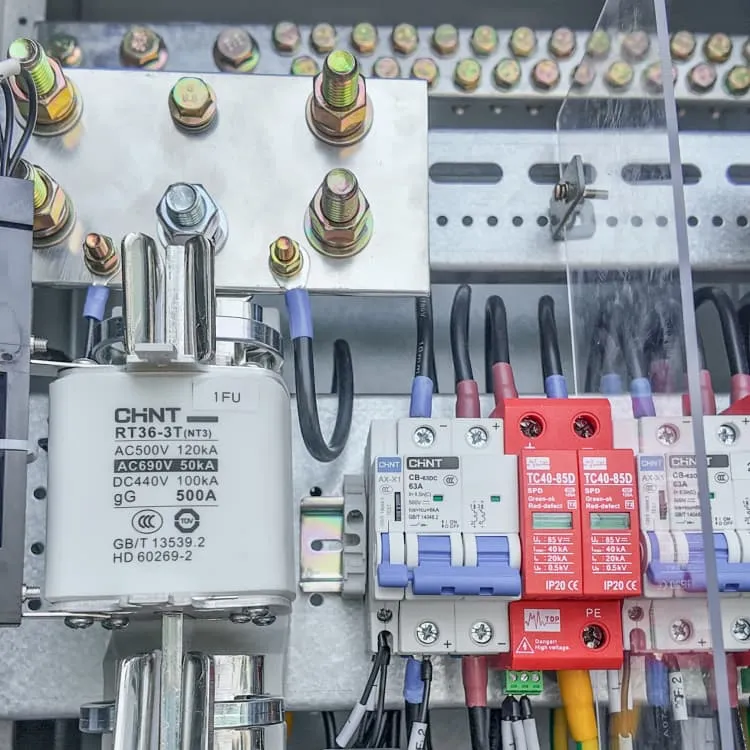

A lithium-ion battery manufacturing plant is a facility designed for the large-scale production of rechargeable battery cells used in various modern technologies. These plants carry out a series of precision-driven processes, including electrode preparation, cell assembly, electrolyte filling, formation, and quality testing.

What is capital investment in a lithium-ion battery manufacturing plant?

Capital Investment (CapEx): For a lithium-ion battery manufacturing plant, machinery represents the most significant portion of total capital investment, accounting for majority of the total CapEx. This includes specialized equipment for electrode processing, cell assembly, electrolyte injection, and testing systems.

Will a lithium-ion battery recycling facility generate 250 jobs?

In September 2024, LOHUM Cleantech Ltd, ReElement Technologies, and American Metals partnered to establish a USD 30 Million lithium-ion battery recycling facility in the U.S. With a 15.5 GWh capacity, it will generate 250 jobs focused on sustainability.

What equipment is required for lithium-ion battery production?

Equipment Selection: Advanced and high-precision machinery is required for each stage of the lithium-ion battery production process. Key equipment includes slurry mixers, extrusion coating machines, die-cutting units, stacking machines, welding lines, drying units, and liquid injection systems.

What is advanced lithium battery pack design?

Advanced Lithium Battery Pack Design: These custom batteries are made when the customer has special requests for temperature capabilities, dimensions, discharge current, and/or battery cycles. In this case, our chemistries, enclosure, and battery management system (BMS) experts are required to monitor each project closely.

Related links

- Moldova pack lithium battery equipment production plant

- Comoros outdoor communication battery cabinet production equipment

- Ah lithium battery pack production

- Madagascar pack lithium battery production

- Single lithium battery pack equipment

- Niger pack lithium battery equipment

- Lithium battery pack balanced charging and discharging equipment

- How much does a lithium battery for energy storage cost in Comoros

- El Salvador lithium iron phosphate battery pack

- Iraq 70kwh lithium battery pack