Single crystal all-black module manufacturing

Welcome to our dedicated page for Single crystal all-black module manufacturing! Here, we have carefully selected a range of videos and relevant information about Single crystal all-black module manufacturing, tailored to meet your interests and needs. Our services include high-quality Single crystal all-black module manufacturing-related products and solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

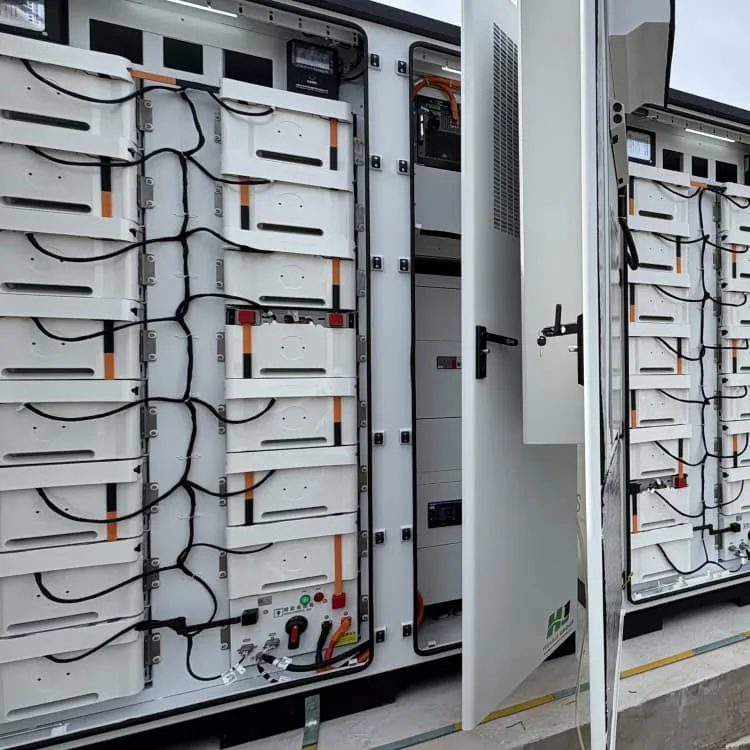

Wherever you are, we're here to provide you with reliable content and services related to Single crystal all-black module manufacturing, including cutting-edge home energy storage systems, advanced lithium-ion batteries, and tailored solar-plus-storage solutions for a variety of industries. Whether you're looking for large-scale industrial solar storage or residential energy solutions, we have a solution for every need. Explore and discover what we have to offer!

Monocrystalline silicon: efficiency and manufacturing process

In addition to the low production rate, there are also concerns about wasted material in the manufacturing process. Creating space-saving solar panels requires cutting circular

Monocrystalline Solar Modules for PV Projects | Targray

Our mono PV module solutions are ideally suited to the evolving needs of today''s photovoltaics industry. Trusted by solar project developers, EPCs, installers and contractors worldwide, our

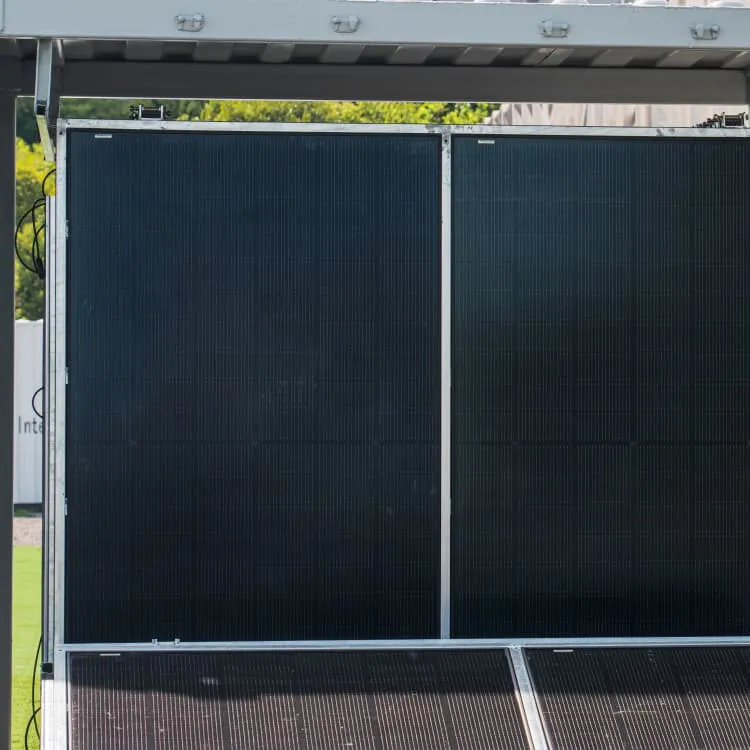

SINGLE CRYSTAL SOLAR MODULES

Because of their monocrystalline structure, black solar panels absorb light and generate electricity more efficiently than polycrystalline blue solar panels.. Monocrystalline solar panels have black

Monocrystalline Solar Modules for PV Projects | Targray

Our mono PV module solutions are ideally suited to the evolving needs of today''s photovoltaics industry. Trusted by solar project developers, EPCs, installers

Monocrystalline silicon

Monocrystalline silicon is generally created by one of several methods that involve melting high-purity, semiconductor-grade silicon (only a few parts per

What are Mono-PERC solar panels?

Monocrystalline cells (Mono) are made from a single crystal of silicon. They boast excellent efficiency, superior low-light performance, and a long lifespan as a result of their

The Pros and Cons of Monocrystalline Solar Panels

The manufacturing process for monocrystalline solar panels involves growing a single crystal of silicon, which is then sliced into thin wafers. This process

All-Black Photovoltaic Modules: An Elegant Solar Solution

Here, we will explore all-black photovoltaic modules'' characteristics, manufacturing steps, advantages, and potential downsides. Key Characteristics and Manufacturing Steps

The Process of Making Solar Cells: From Silicon to

The journey is rooted in manufacturing solar technology. We''ll explore the solar cell manufacturing process, from raw materials to green

High Efficiency TOPCon Modules Product White Paper

Furthermore, CSI Solar challenges conventional norms by optimizing module design to align with container dimensions. This evolution includes upgrading from the 182 TOPCon(182*182) to the

Monocrystalline solar panels – Uses, Benefits and

The manufacturing method and effectiveness of monocrystalline solar panels vary from those of polycrystalline and thin-film solar panels.

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. While some concentrating solar-thermal manufacturing exists, most solar

What is the difference between 60 Half

As a supplier of 60 Half - cell All - black Modules, I often encounter questions from customers about the differences between these high - end solar modules and traditional polycrystalline

Monocrystalline silicon: efficiency and manufacturing

In addition to the low production rate, there are also concerns about wasted material in the manufacturing process. Creating space-saving solar

China All Black Solar Panels,Pure Black Solar Panels,Best All Black

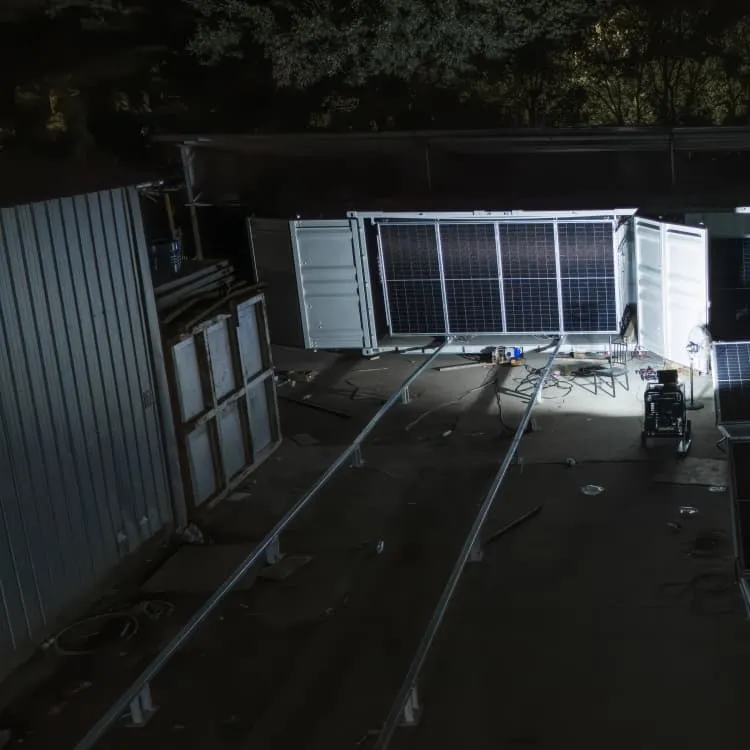

Бренд: SUNKET All Black Solar PV Module All Black Modules are ideal for use in roofs, carports and building photovoltaics (BIPV). The black roof and building façade are fashionable and

Single crystal all black components

Leading production technology provides you with double glass photovoltaic module with a thickness limit of 5.55mm The special design of the junction box enables it to install the frame

Monocrystalline solar panels – Uses, Benefits and Drawbacks

The manufacturing method and effectiveness of monocrystalline solar panels vary from those of polycrystalline and thin-film solar panels. Polycrystalline solar panels are made

Module Manufacturing

The module manufacturing process begins with plating copper (Cu) round ribbons with solder and connecting the silver bushars in a process known as Tabbing and Stringing.

China All Black Solar Panels,Pure Black Solar

EU warehouse all-black mono solar panel 400w 410w Unit Price: USD 0.24 - 0.26 / Others Brand: SUNKET All Black Solar PV Module All Black Modules are

Monocrystalline silicon

Monocrystalline silicon is generally created by one of several methods that involve melting high-purity, semiconductor-grade silicon (only a few parts per million of impurities) and the use of a

Monocrystalline Silicon Cell

The manufacturing process of the wafer, all of it, a single crystal of silicon, which will constitute the cell, begins by extracting the silicon from the sand. In this first extraction process, silicon still

Black solar panels vs blue solar panels: Which is better?

Black solar panels are made from a single, high-quality silicon crystal which wasted in the production of black solar cells.

WHAT ARE MONOCRYSTALLINE AND

Monocrystalline solar modules As monocrystalline solar modules are made up of single-crystal silicon, the process of manufacturing them is

Monocrystalline photovoltaic panels: what they are and their

With no visible solder joints and optimal energy management, these monocrystalline modules guarantee high performance and long life, making them ideal for

The Pros and Cons of Monocrystalline Solar Panels

The manufacturing process for monocrystalline solar panels involves growing a single crystal of silicon, which is then sliced into thin wafers. This process ensures that the silicon material

FORMATION AND APPLICATIONS OF SINGLE

PDF | The single crystal is essentially a single giant grain in which the arrangement of molecules exhibits strict order. Due to this, the crystal... |

Monocrystalline Silicon Cell

The cells were made from thin slices or wafers cut from a single crystal of silicon or from the block of crystals. The former, called monocrystalline silicon cells, were highly efficient, but their

PV Modules | PDF | Thin Film Solar Cell | Single Crystal

The document provides a list of photovoltaic modules that are eligible for incentives in California in accordance with SB1 guidelines. It notes that

Crystalline Silicon Photovoltaic Module Manufacturing Costs

Fully functioning, quality manufacturing equipment is also available for purchase from different equipment vendors, and all vendors are generally willing to sell to almost anyone in the world

Related links

- Single crystal double glass module reinforcement

- Single crystal photovoltaic panel 280w size

- Perc single crystal component loss

- Does the single crystal photovoltaic panel have attenuation

- How much does a single crystal photovoltaic panel cost

- How many watts does a 300w single crystal solar cell have

- Niger single glass photovoltaic module panels

- Single crystal photovoltaic panel micro

- Which photovoltaic panel is better single crystal or dual crystal

- How many watts does a single crystal solar panel hold