Processing and production of outdoor solar integrated machine

Welcome to our dedicated page for Processing and production of outdoor solar integrated machine! Here, we have carefully selected a range of videos and relevant information about Processing and production of outdoor solar integrated machine, tailored to meet your interests and needs. Our services include high-quality Processing and production of outdoor solar integrated machine-related products and solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

Wherever you are, we're here to provide you with reliable content and services related to Processing and production of outdoor solar integrated machine, including cutting-edge home energy storage systems, advanced lithium-ion batteries, and tailored solar-plus-storage solutions for a variety of industries. Whether you're looking for large-scale industrial solar storage or residential energy solutions, we have a solution for every need. Explore and discover what we have to offer!

Solar panel production equipment and machinery

To the machinery and solar panel production equipment are then added a series of services provided by the equipment supplier, such as training activities prior to delivery of the

Process design and feasibility study of food-grade salt

Ultimately, the integrated process of grinding, washing, draining, drying, and fortifying crude solar salt efficiently converts it into high-quality food-grade salt, achieving minimal impurity loss

Reliable Solar Panel Making Machine Supplier

Covering the entire process, we are your one-stop solution for solar panel making equipment. Customization options available. Quality parts. Talk to us.

MANUFACTURING PROCESS FLOWCHART COMPLETE GUIDE

Contact online >> Photovoltaic panel production process training room Solar manufacturing encompasses the production of products and materials across the solar value chain. This

Solar Photovoltaic Panel Production Line Assembly

The photovoltaic panel production line is a highly automated manufacturing process that involves precise testing, classification, welding, and

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on several manufacturing processes

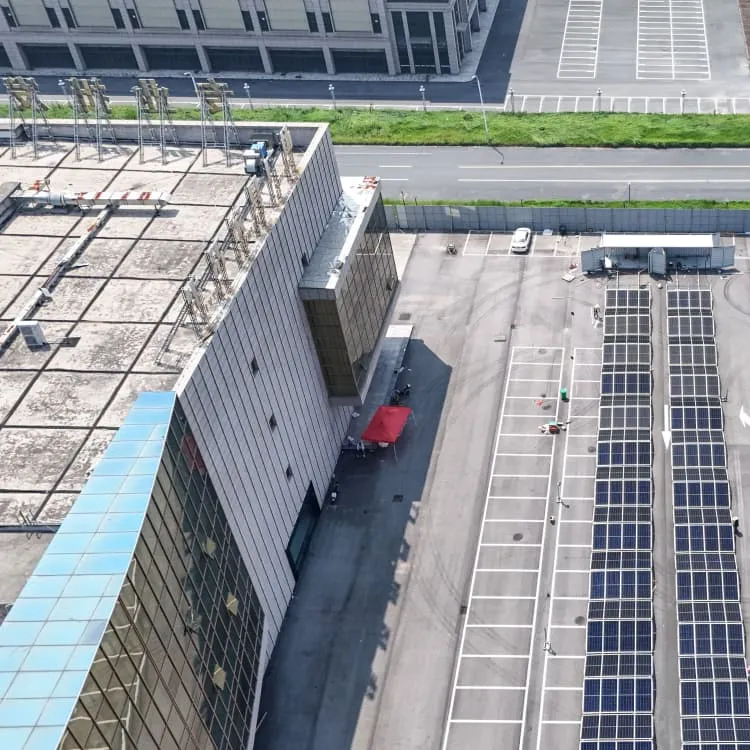

Powering Manufacturing Plants with Solar:

Discover how engineering innovation powers manufacturing with solar energy, reducing costs, boosting efficiency, and leading sustainability efforts.

SOLAR/PV EQUIPMENT – Semiphoton

Our automated Solar/PV modules production line includes a complete set of equipment, such as solar cells laser cutting, string soldering, welding, glass loading, layup, laminating, framing, J

Solar panel production

Integrated solutions for power supply, automation, and digitalization enable the flexible, efficient, and sustainable production of solar panels of the highest

Solar panel production

Integrated solutions for power supply, automation, and digitalization enable the flexible, efficient, and sustainable production of solar panels of the highest quality.

Harnessing Solar Power: A Comprehensive Guide to Solar Panel Machine

Solar panel production lines are integrated systems where various machines perform specific tasks sequentially, from raw material processing to final assembly and testing,

Solar Panel Manufacturing Automation: How Smart

By integrating advanced robotics, artificial intelligence, and smart manufacturing systems, the solar industry has dramatically improved

The Role of Machinery in PV Production | Eco Green

AI and Machine Learning Integration Artificial intelligence (AI) is beginning to play a critical role in solar production. AI-powered machines monitor every aspect

Harnessing Solar Power: A Comprehensive Guide to Solar Panel

Solar panel production lines are integrated systems where various machines perform specific tasks sequentially, from raw material processing to final assembly and testing,

SOLAR/PV EQUIPMENT – Semiphoton

Our automated Solar/PV modules production line includes a complete set of equipment, such as solar cells laser cutting, string soldering, welding, glass

Automation in Solar Panel Production: Transforming

Explore how automation is revolutionizing solar panel production, enhancing efficiency, reducing costs, and ensuring scalability in renewable energy

How to adjust the temperature of solar integrated machine

To adjust the temperature of a solar integrated machine, follow these essential steps: 1. Determine the desired temperature range using the machine''s specifications, 2.

Solar Panel Manufacturing Plant Project Report 2024: Unit

Product Overview: Comprehensive description of the solar panel product and its characteristics. Unit Operations Involved: Step-by-step breakdown of the various operations in

IJRTI

In conclusion, the development of the solar-powered portable semi- automatic pellet machine with an integrated shredder and mixer assembly represents a significant stride toward sustainable

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on

Solar Panel Manufacturing Automation: How Smart Factories Are

By integrating advanced robotics, artificial intelligence, and smart manufacturing systems, the solar industry has dramatically improved production efficiency while reducing

Powering Manufacturing Plants with Solar: Engineering the

Discover how engineering innovation powers manufacturing with solar energy, reducing costs, boosting efficiency, and leading sustainability efforts.

How to Set Up a Solar Glass Manufacturing Plant: Process

The manufacturing process for solar glass involves several precision-driven steps to ensure the production of high-quality, high-transmittance glass suitable for solar applications:

Automation solutions for the photovoltaic industry

From control technology, electric drives, and pneumatics through to linear and assembly technology, Rexroth covers the entire product portfolio for photovoltaic automation.

Automation in Solar Panel Production: Transforming the Future

Explore how automation is revolutionizing solar panel production, enhancing efficiency, reducing costs, and ensuring scalability in renewable energy manufacturing.

Solar Panel Making Machines: A Guide to the Production Process

In this comprehensive guide, you will discover a fundamental overview of solar panel making machines and production processes essential for understanding solar panel

Solar panels manufacturing machines: our proposal

Published: 20 July 2016 2022-> Discover the latest Solar panels'' production & testing machines from Ecoprogetti Srl by clicking here. FROM 20

(PDF) Recent advances in solar drying technologies:

On the one hand, a hybrid dryer integrated with a solar panel produces electricity for the operation of a DC blower circulating hot air inside

Solar panel production equipment and machinery

Discover the latest Solar panels'' production & testing machines from Ecoprogetti Srl by clicking here. Solar panel production equipment and machinery. Nowadays the solar

Powering the Future: Inside the Solar PV Cell

Conclusion The PV cell manufacturing process is a complex and precise endeavor that transforms raw materials into high-efficiency solar cells.

FAQs 6

How does solar manufacturing work?

How Does Solar Work? Solar manufacturing encompasses the production of products and materials across the solar value chain. While some concentrating solar-thermal manufacturing exists, most solar manufacturing in the United States is related to photovoltaic (PV) systems.

How automation is transforming the solar energy industry?

In the rapidly evolving solar energy sector, automation in solar panel production is emerging as a cornerstone of modern manufacturing processes. By integrating advanced technologies like AI, robotics, and IoT, companies such as Rayzon Solar are redefining how solar panels are designed, assembled, and distributed.

What is automation in solar panel production?

Automation in solar panel production involves leveraging technologies such as robotics, machine learning, and smart sensors to optimize the entire manufacturing process. From silicon wafer slicing to module assembly, these technologies minimize human intervention while maximizing accuracy and speed.

Why do we need automated solar panel manufacturing practices?

With demand for renewable energy surging, the need for modern solar panel manufacturing practices has never been greater. Automated processes are addressing challenges like labour shortages, cost efficiency, and product consistency, making solar panels more accessible and reliable than ever.

How are solar panels manufactured?

Nowadays the solar panels’ production equipment is divided into the following required machinery and accessories. The first run automated processes are the stringing and lamination, but also the analysis of quality as electroluminescence tests. These and other procedures are indispensable for the correct manufacture of the module in each component.

How can solar energy be used in manufacturing?

Implementing solar energy in manufacturing requires a structured engineering approach to align renewable energy systems with operational workflows. Large automotive companies, for example, have successfully integrated solar solutions into their facilities by collaborating with engineering teams to optimize energy flow and system design.

Related links

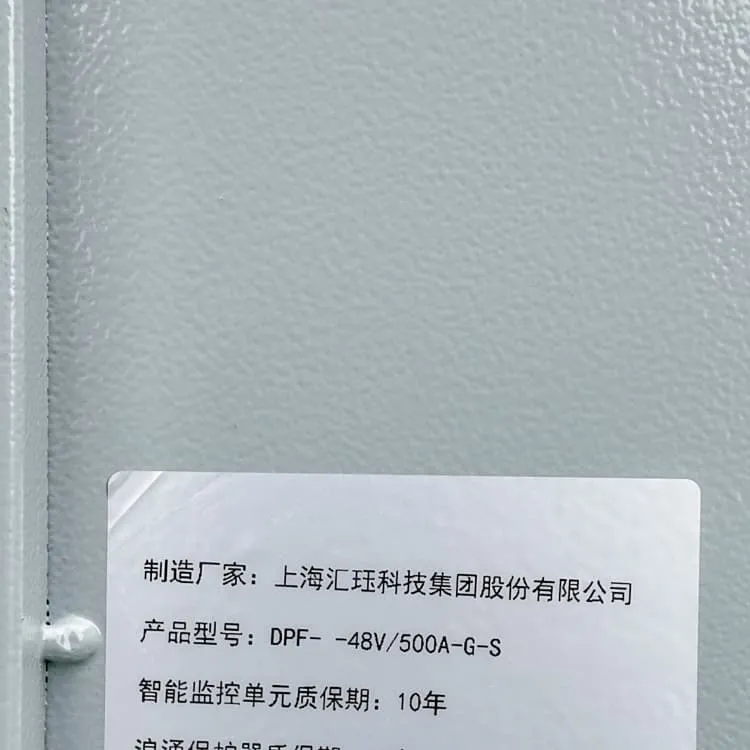

- Outdoor solar integrated machine battery storage

- Home solar integrated machine outdoor courtyard

- Solar integrated machine courtyard outdoor

- Combined outdoor solar integrated machine

- Outdoor solar integrated machine anti-corrosion

- Outdoor solar integrated machine with multi-angle adjustment

- High-power energy storage solar integrated machine outdoor

- Cuba outdoor solar integrated machine

- Iceland outdoor staircase solar integrated machine

- Garden outdoor solar integrated machine