Solar photovoltaic modules and polysilicon

Welcome to our dedicated page for Solar photovoltaic modules and polysilicon! Here, we have carefully selected a range of videos and relevant information about Solar photovoltaic modules and polysilicon, tailored to meet your interests and needs. Our services include high-quality Solar photovoltaic modules and polysilicon-related products and solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

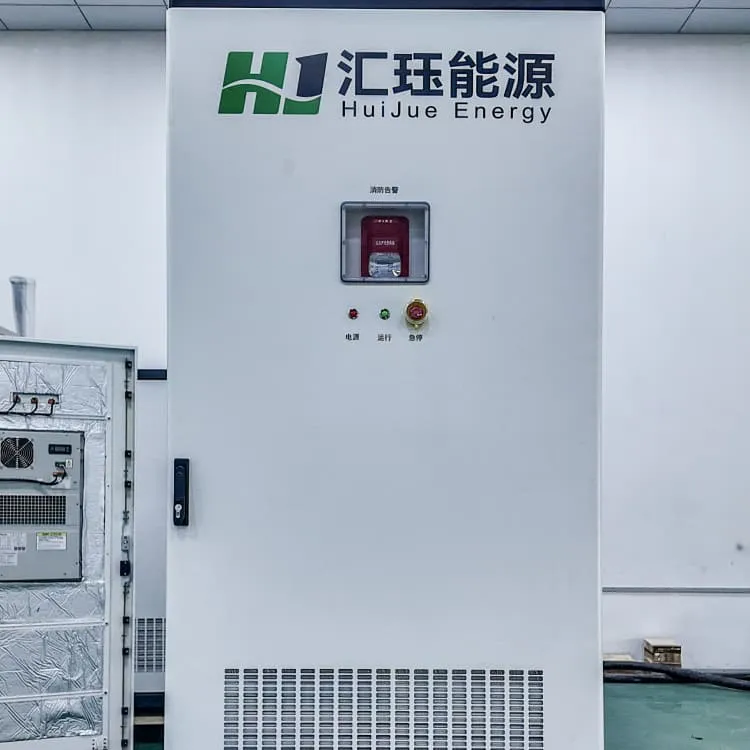

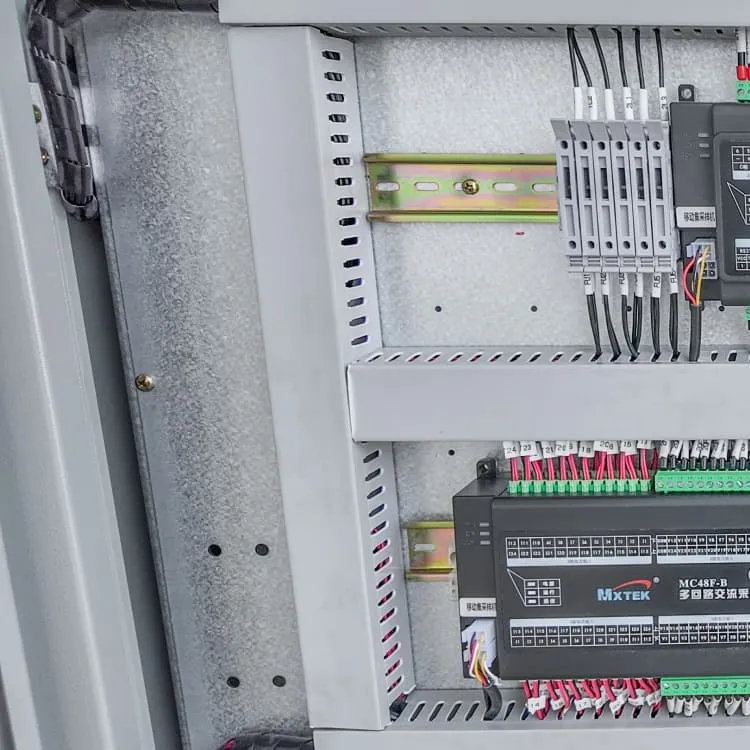

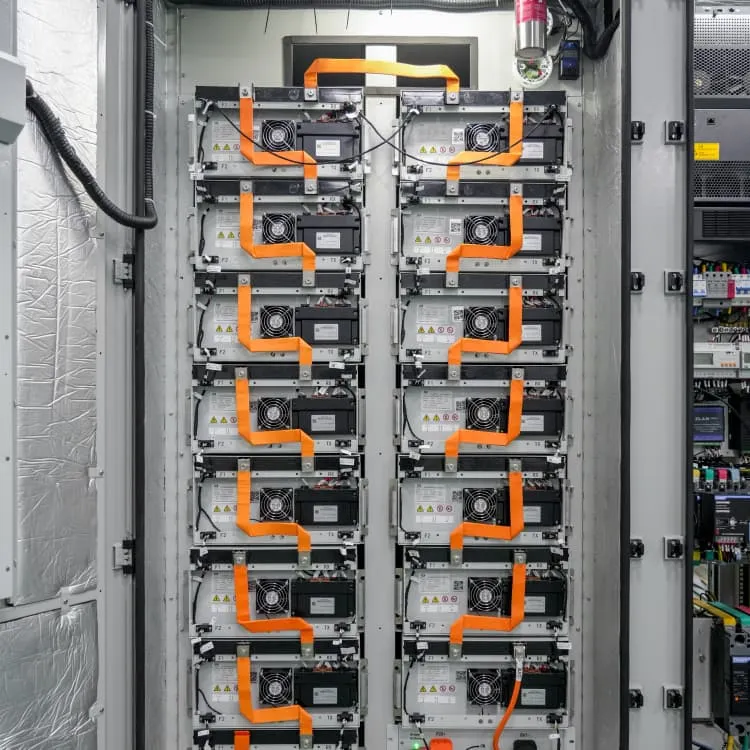

Wherever you are, we're here to provide you with reliable content and services related to Solar photovoltaic modules and polysilicon, including cutting-edge home energy storage systems, advanced lithium-ion batteries, and tailored solar-plus-storage solutions for a variety of industries. Whether you're looking for large-scale industrial solar storage or residential energy solutions, we have a solution for every need. Explore and discover what we have to offer!

US finalises Section 301 tariffs, proposes 50% duty on wafers and

Among the 19 exclusions, five were for equipment to manufacture solar modules, six for equipment to manufacture solar cells and the remaining eight for equipment to

Corning, Suniva, Heliene to produce first fully US

Corning, Suniva and Heliene are combining their strengths to produce what will be the first solar module with polysilicon, wafers and cells

A Polysilicon Learning Curve and the Material Requirements for

Herein, the current and future projected polysilicon demand for the photovoltaic (PV) industry toward broad electrification scenarios with 63.4 TW of PV installed by 2050 is

What is Polysilicon?

The process for making silicon based Solar PV modules is as follows: Polysilicon is melted at extremely high temperatures into a liquid state and a silicon crystal ingot is grown from the

Solar Photovoltaic Manufacturing Basics

Most commercially available PV modules rely on crystalline silicon as the absorber material. These modules have several manufacturing steps that typically occur separately from each other.

Life cycle assessment of polysilicon photovoltaic modules with

Polysilicon photovoltaic (PV) modules are about to enter the end-of-life (EOL) stage on a large scale, and making the exploration of effective recycling methods and

The current state of U.S. polysilicon production – pv magazine

U.S. solar module manufacturing has grown fivefold since supportive legislation passed in 2022. Over that time, 70 new solar and energy storage manufacturing facilities have

US doubles solar polysilicon and wafer tariffs on China

The US government has doubled Section 301 tariffs on imported solar polysilicon and wafers from China to 50%. The materials are vital for manufacturing solar panels, from

System Dynamics of Polysilicon for Solar Photovoltaics: A

For example, high-purity polysilicon, a key material in solar photovoltaics, has experienced significant price fluctuations, affecting the manufacturing capacity and cost of both polysilicon

Photovoltaic Cell (Polysilicon/ Wafers)

Solar cells and modules A photovoltaic (PV) cell, commonly called a solar cell, is a nonmechanical device that converts sunlight directly into electricity. A PV cell is made of semiconductor

Polysilicon Production

The production and purification of polysilicon is the first step in the manufacturing process to produce conventional silicon solar cells. The fabrication of

Solar Photovoltaic Manufacturing Basics

Most commercially available PV modules rely on crystalline silicon as the absorber material. These modules have several manufacturing steps that

The current state of U.S. polysilicon production – pv

U.S. solar module manufacturing has grown fivefold since supportive legislation passed in 2022. Over that time, 70 new solar and

What is polysilicon and how is it made? — RatedPower

Because of this, polysilicon is crucial to the solar industry as it plays a key part when manufacturing solar cells that are used in solar panels.

Polysilicon Price: Chart, Forecast, History

Price data providers: A short guide for users Three Taiwanese market research firms provide weekly spot prices of the products in the solar value chain – solar-grade

An introduction to solar Polycrystalline Modules

Polycrystalline silicon (polysilicon) is the material used to manufacture crystalline silicon PV modules and consists of small silicon

What is polysilicon used for in solar?

Polysilicon is pivotal in the solar industry, serving as a fundamental element in creating photovoltaic cells, the essential units of solar panels. The high purity and crystalline

What you need to know about polysilicon and its role in solar

The role of polysilicon in solar cells, how it plays a vital role in photovoltaic technology, and advancements in polysilicon production that are

Achieving American Leadership in the Solar Photovoltaics

U.S. Solar Market and Supply Chain Overview The solar supply chain: Polysilicon is melted to grow monocrystalline silicon ingots, which are sliced into thin silicon wafers. Silicon wafers are

The difference between monocrystalline silicon and

The magical silicon wafer that converts solar energy into electrical energy is the core of photovoltaic technology. Today, let''s take a closer look at

Solar price trend

Energytrend is a professional platform of green energy, offering latest price of solar PV industry.

3Q 2024 Global PV Market Outlook

The global PV industry is expected to install 592 gigawatts of modules this year, up 33% from the boom year of 2023. Low prices for

What is polysilicon used for in solar?

Polysilicon is pivotal in the solar industry, serving as a fundamental element in creating photovoltaic cells, the essential units of solar

Polycrystalline silicon

While polysilicon and multisilicon are often used as synonyms, multicrystalline usually refers to crystals larger than one millimetre. Multicrystalline solar cells are the most common type of

Polysilicon Solar PV Price

1 day ago· All solar PV (Photovoltaic) real-time price update, such as Panle/Module, Inverter, Wafer, Cell, and poly / Silicon, and research reports.

A Polysilicon Learning Curve and the Material

Herein, the current and future projected polysilicon demand for the photovoltaic (PV) industry toward broad electrification scenarios with 63.4 TW

What is polysilicon used for in solar?

Polysilicon serves as a foundational material in the solar industry for making solar cells, integral components of solar panels. It is crucial due to

What you need to know about polysilicon and its role in solar modules

Polysilicon, a high-purity form of silicon, is a key raw material in the solar photovoltaic (PV) supply chain. To produce solar modules, polysilicon is melted at high

The Role of Polysilicon in the Solar PV Industry A Deep Dive

The role of polysilicon in solar cells, how it plays a vital role in photovoltaic technology, and advancements in polysilicon production that are driving the future of solar

FAQs 6

What is polysilicon and how is it used in solar PV?

Polysilicon is an initial building block for the process of manufacturing silicon-based solar PV. In the process of making silicon-based Solar PV modules, polysilicon is melted at extremely high temperatures into a liquid state and a silicon crystal ingot is grown from the resulting melt.

Can polysilicon be used for photovoltaic cells?

Polysilicon for photovoltaic cells will help lead the solar industry with ongoing innovations for purification, manufacturing, and cell design. The landscape for high-purity polysilicon for solar has never been more innovative or efficient—and the results are bearing out in a more affordable green energy future.

What is polysilicon used for?

Polysilicon, a high-purity form of silicon, is a key raw material in the solar photovoltaic (PV) supply chain. To produce solar modules, polysilicon is melted at high temperatures to form ingots, which are then sliced into wafers and processed into solar cells and solar modules. Source: National Renewable Energy Laboratory, 2021

How are silicon based solar PV modules made?

Silicon-based Solar PV modules are manufactured through the following process: Polysilicon is melted at extremely high temperatures into a liquid state and a silicon crystal ingot is grown from the resulting melt. The ingots are then squared and sliced very thinly into wafers.

How is polysilicon produced?

Polysilicon is produced by melting it at extremely high temperatures into a liquid state and growing a silicon crystal ingot from the resulting melt\. The ingots are then squared, sliced very thinly into wafers, and processed into solar cells to convert sunlight into electricity. Solar cells are strung together and framed into a module.

What is the difference between polysilicon and multicrystalline solar cells?

While polysilicon and multisilicon are often used as synonyms, multicrystalline usually refers to crystals larger than one millimetre. Multicrystalline solar cells are the most common type of solar cells in the fast-growing PV market and consume most of the worldwide produced polysilicon.

Related links

- Silicon solar photovoltaic modules

- Solar panels installed on rooftop photovoltaic modules

- Understanding solar cells and photovoltaic modules

- Central Asia Solar Cell Photovoltaic Modules

- New lightweight solar photovoltaic modules

- Thailand thin film photovoltaic modules solar panels

- Huawei solar photovoltaic modules

- Thailand crystalline silicon photovoltaic modules solar panels

- Canadian solar photovoltaic modules

- Solar photovoltaic panels for rural households in Europe