Battery cabinet assembly production integrated system

Welcome to our dedicated page for Battery cabinet assembly production integrated system! Here, we have carefully selected a range of videos and relevant information about Battery cabinet assembly production integrated system, tailored to meet your interests and needs. Our services include high-quality Battery cabinet assembly production integrated system-related products and solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

Wherever you are, we're here to provide you with reliable content and services related to Battery cabinet assembly production integrated system, including cutting-edge home energy storage systems, advanced lithium-ion batteries, and tailored solar-plus-storage solutions for a variety of industries. Whether you're looking for large-scale industrial solar storage or residential energy solutions, we have a solution for every need. Explore and discover what we have to offer!

215 kWh LFP Air Cooled Battery System | HISbatt

At HIS-Energy our aim is to deliver our clients with fully integrated turnkey battery storage solutions. HISbatt 215-A comes with an integrated cooling system

Module and PACK Line (Energy Storage Battery)_Intelligent

The equipment has the advantages of automatic intelligent assembly and production from prismatic aluminum shell cell to module and then to PACK box, improving product quality

Top 10 Battery Assembly Line Equipment

Discover the top 10 battery assembly line factory manufacturer suppliers for 2025. Learn how to select the best equipment for your production

Intensium Energy Storage Systems | Saft | Batteries

Saft, has extended its energy storage system (ESS) offering with the launch of its latest innovation: the Intensium® Flex (I-Flex) battery storage container. It

EV Battery Production. Optimized.

Our tailored MES for battery is built to manage hybrid production. So you can take a simpler and apply one, integrated and information-enabled across your operations. A typical gigafactory

Lithium-ion Battery Module and Pack Production Line Process Flow

These systems are used to harmonize and connect the various units and equipment to achieve efficient operation of the entire production line and management of

Optimize Battery Assembly Line with Design and Automation

Discover the key features of a modern battery pack assembly line and how expert design and automation can boost performance, flexibility and output.

Energy Storage Systems | Eqube Power

The system reduces delays caused by equipment coordination and inspections, with all wiring, interconnects, and accessories thoroughly tested after

Lithium-ion Battery Module and Pack Production Line

These systems are used to harmonize and connect the various units and equipment to achieve efficient operation of the entire production line

Advanced New Energy Lithium Battery PACK Automated Assembly Production

This state-of-the-art production line achieves seamless automated battery pack production. Spanning an impressive 16 meters, it integrates cutting-edge technology through the following

Battery Assembly Line Design, Build, and Scaling

Re:Build Battery Solutions designed and implemented an automated lithium battery production and assembly system, optimizing materials handling, equipment integration, and process

The Ultimate Guide to Lithium-Ion Battery Storage Cabinets

Discover the importance of lithium-ion battery storage cabinets for safe battery storage and charging. Learn best practices, key features, and how to choose the right battery

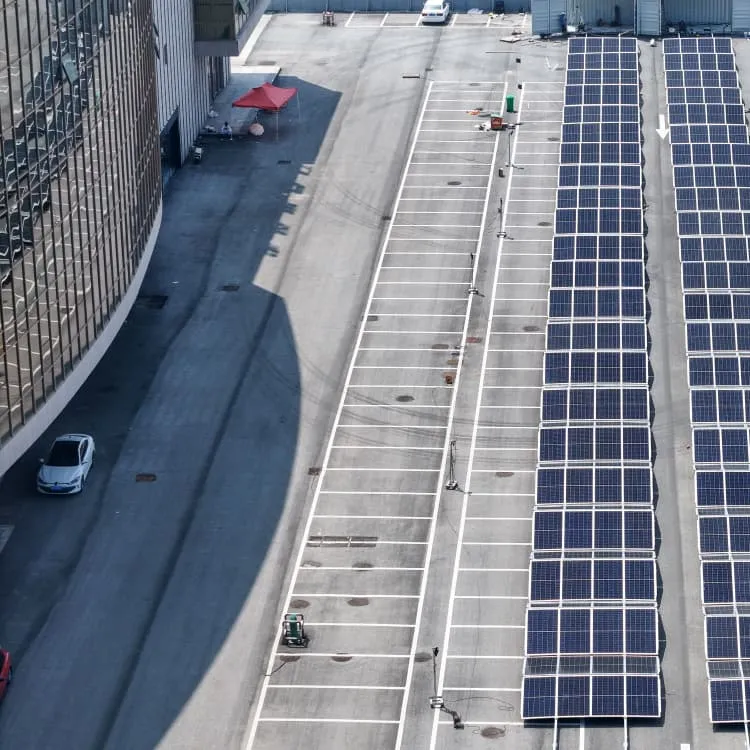

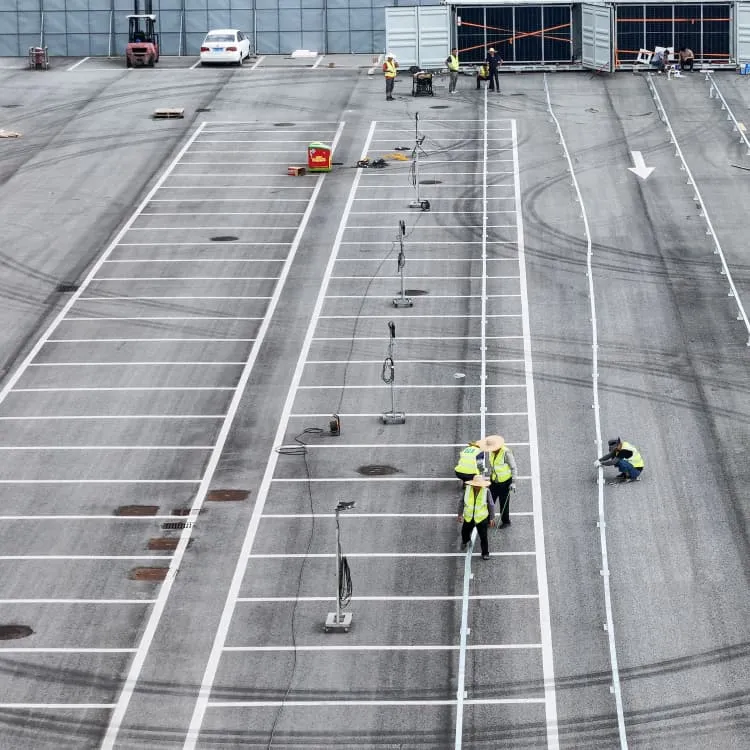

Flexible production of battery cabinets

The flexible zinc-ion batteries adopt a common planar battery configuration, with simple structure, simple assembly processes, and an energy density from 50 Wh/L to 100 Wh/L

The Role of Battery Cabinet Systems in Modern Energy Storage

A battery cabinet system is an integrated assembly of batteries enclosed in a protective cabinet, designed for various applications, including peak shaving, backup power,

Battery Module & Pack Manufacturing: Step-by-Step

Interested in setting up or upgrading your Li-ion battery pack assembly line with smart, scalable turnkey solutions? Contact us to discover how our equipment partners can

Battery Assembly Line Design, Build, and Scaling

Re:Build Battery Solutions designed and implemented an automated lithium battery production and assembly system, optimizing materials handling,

Battery integrated cabinet assembly tutorial diagram

Use the Electrical Engineering drawing type in Visio Professional or Visio Plan 2 to create electrical and electronic schematic diagrams. On the File tab, select New, and then search for

Mastering the Battery Pack Assembly Process: A Comprehensive

The BMS, which monitors the health and performance of the battery pack, is integrated into the assembly. This system tracks key parameters like voltage, temperature,

Assembly line for battery modules and battery packs

For cell/module pack assembly, PIA Automation offers flexible and highly automated systems for the efficient production of battery cells, modules, and battery packs. These systems are

A Guide to Battery Energy Storage System

A battery energy storage system (BESS) contains several critical components. This guide will explain what each of those components does.

Battery Module & Pack Manufacturing: Step-by-Step

Interested in setting up or upgrading your Li-ion battery pack assembly line with smart, scalable turnkey solutions? Contact us to discover

Mastering the Battery Pack Assembly Process: A

The BMS, which monitors the health and performance of the battery pack, is integrated into the assembly. This system tracks key

EV Battery Production. Optimized.

The integrated solution also expands to module and production seamlessly manages and tracks your prismatic, cylindrical pack assembly to enable seamless traceability of battery

In-Depth Overview of Battery Cell Assembly Processes

Thorough knowledge of battery cell assembly is imperative for driving innovations in storage technology and addressing emerging energy demands. Prologue to

BATTERY ENERGY STORAGE SYSTEMS

A. Battery manufacturing and testing B. PCS manufacturing and testing C. Container assembly

battery cabinet,battery storage cabinet,battery bank

EverExceed VRL A battery assembly cabinets are very durable, and easy to install. Engineered for use with most type of battery terminal models, these

Advanced New Energy Lithium Battery PACK

This state-of-the-art production line achieves seamless automated battery pack production. Spanning an impressive 16 meters, it integrates cutting-edge

Energy Storage Systems | Eqube Power

The system reduces delays caused by equipment coordination and inspections, with all wiring, interconnects, and accessories thoroughly tested after assembly. Each battery cabinet is a

How to design an energy storage cabinet: integration and

This article will introduce in detail how to design an energy storage cabinet device, and focus on how to integrate key components such as PCS (power conversion system), EMS

(PDF) BATTERY MODULE AND PACK ASSEMBLY PROCESS

Our second brochure on the subject "Assembly process of a battery module and battery pack" deals with both battery module assembly and battery pack assembly. It was our

FAQs 6

What is a lithium-ion battery module & pack production line?

The lithium-ion battery module and pack production line is a complex system consisting of multiple major units and associated equipment that work in concert to achieve high quality lithium-ion module and pack production.

What is a battery pack assembly process?

The battery pack assembly process is a meticulously planned sequence of steps that transforms individual components into a fully functional battery pack. It begins with the procurement of high-quality materials, including battery cells, BMS, wiring, and protective casings.

How does a battery pack assembly line work?

A battery pack assembly line involves several key steps to ensure the final product is safe, high-performing, and ready for use. Here's a breakdown of the main operations: Cell Testing and Sorting: The first step is to test and sort the battery cells. Only the best-performing cells move forward to ensure high-quality output.

What is a pack assembly line?

Pack Assembly Line On the Pack assembly line, the battery modules are assembled into a complete pack, which includes the module casing, the heat dissipation system, the Battery Management Unit (BMU) and so on. 6. Test Equipment

What is battery assembly & BMS integration?

Cell Assembly: Battery cells are arranged in series or parallel configurations to achieve the required voltage and capacity. BMS Integration: The BMS is installed to monitor voltage, temperature, and charging cycles, ensuring safe operation.

Why is battery pack assembly important?

The significance of the battery pack assembly process lies in its direct impact on the performance and safety of the final product. A well-assembled battery pack ensures optimal energy storage, efficient power delivery, and long-term durability.

Related links

- Battery cabinet production integrated system

- What is a new energy battery cabinet assembly

- Battery station cabinet production equipment

- Lithium battery station cabinet automation production price

- What is the new technology of battery cabinet assembly

- Nepal battery cabinet production company

- Energy storage battery assembly automated production equipment

- Energy storage cabinet battery production in El Salvador

- South Ossetia production battery cabinet supplier

- Energy Storage Cabinet Inverter Battery Production Location 372KWh